Football Synthetic turf is a high-performance artificial turf designed specifically for the sport of football. By simulating the shape and mechanical properties of natural grass, it provides athletes with a stable and safe competitive environment. It is made of synthetic fiber material, with a highly simulated grass filament structure and uniform density, ensuring that the rolling trajectory and rebound performance of the sphere are close to natural grasslands.

1. High toughness:

High Dtex S-Shape Football Synthetic Turf uses high-density polyethylene (HDPE) grass fibers, and the single-filament fineness (Dtex) is far higher than that of ordinary turf, ensuring higher wear resistance and tensile strength. Laboratory tests show that its breaking strength is ≥12N, which is much higher than the industry standard (usually 8-10N), and can withstand frequent sprints, sudden stops and dragging of training equipment by professional players. In addition, the roots of the grass fibers use double-twisted braiding technology to enhance the anchoring force, avoid being pulled out by shoe spikes in fierce confrontation, and extend the service life to more than 10 years.

2. Bionics:

The S-shaped grass fiber structure simulates the curved shape of natural grass, and the top of the grass fiber is naturally drooping, making the ball rolling trajectory and rebound height closer to real grass. At the same time, the grass fiber spacing is scientifically calculated to ensure that the interaction between the athlete's foot and the grass fiber is more realistic when changing direction, reducing the common "over-slip" or "over-astringency" problems of artificial turf. FIFA tests show that the ball's rolling resistance (20-25N) and rebound rate (55%-65%) meet top competition standards.

3. Wear resistance:

The surface of Football Synthetic Turf is coated with a special UV stabilizer to resist long-term UV exposure and delay aging. After xenon lamp accelerated aging test (2000 hours), the color change ΔE<3, far better than the industry standard of ΔE<5. In addition, the bottom of the grass is made of tear-resistant base fabric. Even under high-intensity use, the grass shedding rate is <0.5%/year, ensuring the long-term beauty and stable performance of the venue.

4. Stability:

The composite woven adhesive technology (using polyurethane + latex double coating) makes the grass and base fabric more closely combined, with a peel strength of ≥50N/5cm, and remains stable even at low temperatures of -30℃ or high temperatures of 50℃. The base fabric is reinforced with high-strength polyester mesh with a tensile strength of ≥200N/cm² to prevent the venue from deforming due to thermal expansion and contraction or mechanical impact.

5. Drainage:

The patented open-pore base fabric design (aperture 1.5-2mm) combined with vertical drainage grooves allows rainwater to infiltrate quickly, with a drainage rate of ≥30L/m²/h, far exceeding the FIFA requirement of 20L/m²/h. Even in heavy rain, the venue can be restored to use within 20 minutes to avoid water accumulation affecting the game. The base layer can also be equipped with an optional storage and drainage module, which is suitable for areas with high groundwater levels.

6. Buffering:

The Football Synthetic Turf filling layer uses TPE (thermoplastic elastomer) environmentally friendly particles with a particle size of 2-3mm, providing an impact absorption rate of 55%-70% (FIFA standard is 50%), effectively reducing the load on athletes' joints. Laboratory data shows that its vertical deformation (4-6mm) and energy return (35%-45%) are better than traditional rubber particles, reducing the risk of sports injuries.

7. Anti-slip: The surface of the grass is micro-embossed to increase the friction coefficient (dynamic friction coefficient 0.6-0.8), while maintaining moderate slippage to avoid spraining the ankle when turning sharply. Even in a humid environment, its anti-slip performance is still better than that of ordinary grass, making it safer to play in rainy days.

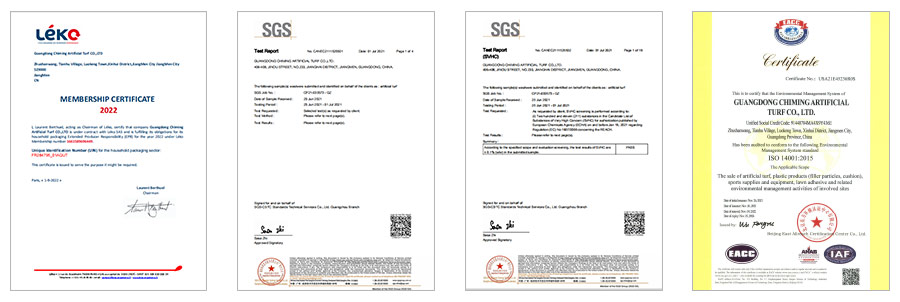

8. Environmental protection: All materials of Football Synthetic Turf have passed SGS and RoHS certification, do not contain heavy metals such as lead and cadmium, and VOC emissions are close to zero. Waste grass can be 100% recycled into products such as runways and floor mats, which meet global green building standards (such as LEED certification).

1. Professional events:

Football Synthetic Turf has passed the FIFA Quality Pro certification. Its grass height (50-60mm) and density (20,000-22,000 clusters/m²) strictly meet international competition standards to ensure the consistency of ball speed, rebound and rolling trajectory. HDTV broadcast tests show that its color reflectivity (60%-70%) is uniform and glare-free, avoiding lens reflection interference.

2. Youth training base:

For players of different age groups, the thickness of the filling layer can be adjusted (25mm is recommended for U12 and 40mm is recommended for U18) to optimize the cushioning performance. The grass rebound force can be customized (20-25mm) to reduce muscle fatigue of young players. In addition, the venue can be integrated with smart sensors to monitor players' running distance, sprint times and other data in real time to assist scientific training.

3. Campus venues:

The high-strength wear-resistant characteristics make it suitable for 6-8 hours of use per day, and it is compatible with multiple events such as football, rugby, and hockey. Different color partitions (such as 5-a-side and 7-a-side markings) can be customized to improve the utilization rate of the venue. Compared with natural grass, the annual maintenance cost is reduced by 70%, which is particularly suitable for schools with limited budgets.

4. Community Park:

Football Synthetic Turf uses CoolTouch® technology, and the surface temperature is 5-8℃ lower than ordinary artificial grass, which can still be used comfortably in summer. It is equipped with detachable fences and night LED lighting modules to create a multi-functional sports space. Community cases show that its utilization rate is 50% higher than that of traditional lawns, promoting residents' fitness activities.

5. International venues:

The modular design (2m×25m roll) supports rapid paving and partial replacement, and is suitable for high temperature (60℃) in the Middle East and extremely cold (-40℃) in Northern Europe. A use case of a sports center in Dubai shows that no major repairs are required within 5 years, and only 5% of the wear area is replaced, which greatly reduces operating costs.

1. Daily cleaning:

Use a vacuum cleaner or soft brush to clean up debris (leaves, gravel, etc.) every week to avoid scratching the grass with hard objects. After spilling drinks or food, rinse with clean water immediately to prevent sugar from adhering and breeding bacteria. Stubborn stains can be wiped with a neutral detergent (pH6-8), and strong acid and alkali solvents are prohibited.

2. Maintenance of the filling layer:

Use a professional rake (tooth pitch ≥30mm) to loosen the filling layer every quarter to ensure that the rubber particles are evenly distributed (thickness 35-40mm). If the particle loss is >10%, it needs to be replenished in time to avoid insufficient local buffering. When freezing in winter, metal tools are prohibited from scraping to avoid damaging the grass.

3. Disinfection and mildew prevention:

Spray diluted hydrogen peroxide (3%) or quaternary ammonium salt disinfectants every month, focusing on high-frequency contact areas such as restricted areas and corner areas. When mold grows, it can be treated with a special mildew inhibitor for grass to prevent the spread of spores.

4. Seasonal inspection:

- Summer: Use water mist to cool down when the temperature is high (avoid large amounts of water flushing that may cause particle loss).

- Winter: Clean up the ground in time after snowfall to prevent snow accumulation from compacting the grass.

- Rainy season: Check if the drainage holes are blocked to ensure smooth drainage.

Every year, hire a professional organization to test the flatness and buffering performance of the site and perform local repairs when necessary.

————————————————————————————————————————————————————

Company Profile

Guangdong Chiming Artificial Turf Co., Ltd. is a leading manufacturer of artificial grass in China, short for CMgrass factory. We have specialized in high-quality, all-weather durable, and safe artificial grass for stadiums, schools, fitness squares, playgrounds, and airports for more than 15 years.

————————————————————————————————————————————————————

Technical Advantages

With environment-friendly materials, new scientific and technological formulations, relying on independent intellectual property rights, CMgrass has launched a number of artificial grass products for different site.

We provide personalized customization services to ensure that the needs of customers are met. Whether it is site size, grass color, material or special needs, we can customize according to customer requirements. This ensures that the grass blends seamlessly with its surroundings, creating a pleasing effect. Whether it is outdoor sports fields, gardens, parks or commercial areas, we can provide you with the best customized artificial turf solutions. Let you have a unique artificial grass experience!

Mobile Phone:

Mobile Phone: Wechart:

Wechart: Contact Now

Contact Now